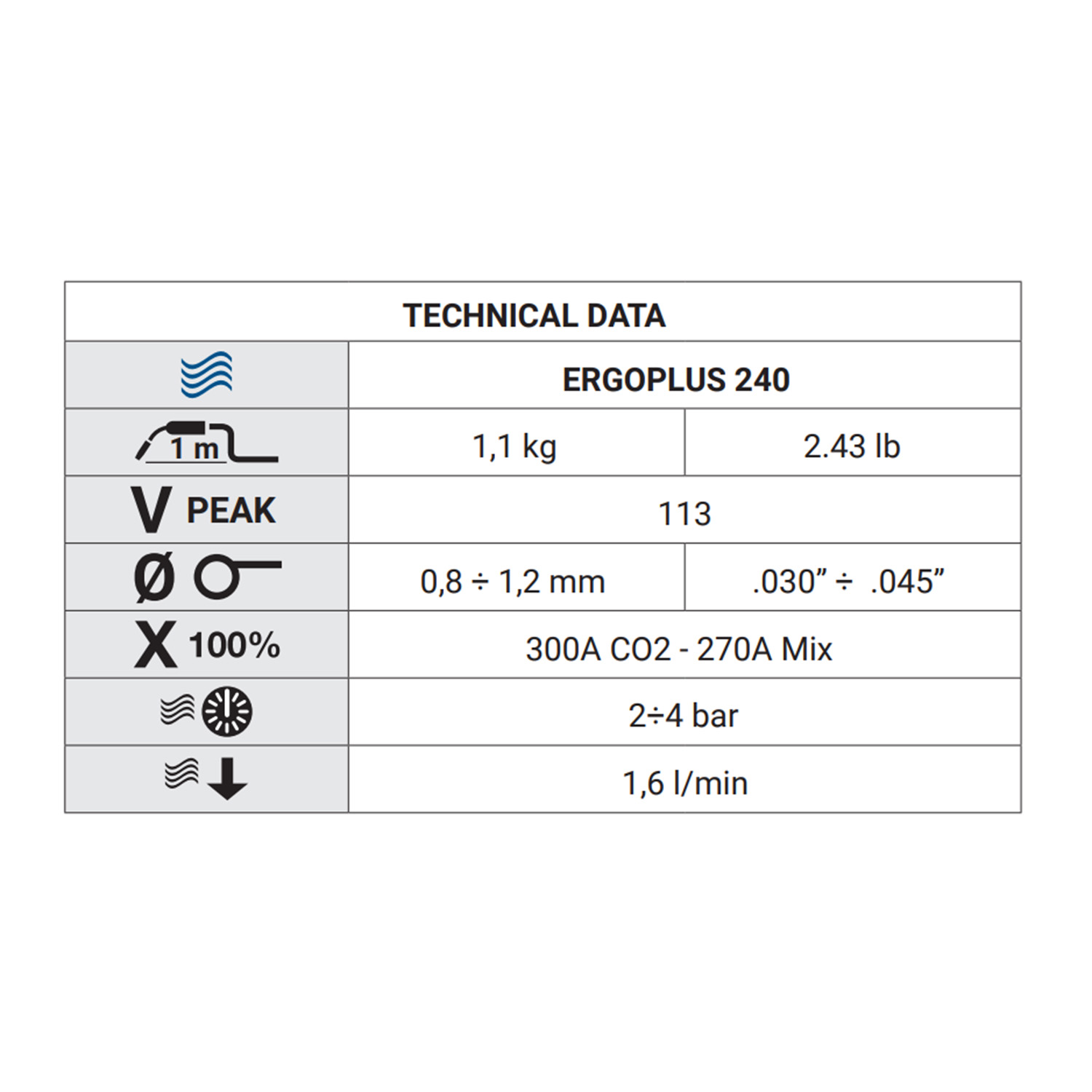

Trafimet Ergoplus 240 Water Cooled MIG Torch

Product Overview

-

The Trafimet Ergoplus MIG torches have been developed and produced to a whole new standard. In addition to the new ergonomic design, significant improvements have been made to the welding performance of the Trafimet Ergoplus MIG torches. The handle of the Ergoplus MIG torches is made of two components, rubber, and plastic. The rubber textures are located on the top and the underside of the handle surface areas, where the human hand needs to hold the handle naturally and precisely. The triangular two directional shape of the handle has been the leading principle in designing the handle of the Trafimet Ergoplus from start to finish and fits the natural position of the human hand. The air-cooled Ergoplus torches have a cleverly designed plastic spring-bending cable support. The plastic spring solution of the Ergoplus is designed to give maximum support to the cable, but with less downwards force, this helps to deliver a superb balance to the torch handle.

Read more

The improved flexible materials and the updated bending cable support, makes the Trafimet Ergoplus MIG torches effortless and comfortable in almost every welding situation. One of the key features in the ergonomic design of the Trafimet Ergoplus torches is a detachable pistol grip handle. When welding using a traditional handle, the welders’ shoulder and elbow muscles are under the constant stress of the workload. With the pistol grip handle the shoulder and elbow position is completely different and the muscle strength load is 25–64% lower depending on the welding position (EMG-measurements made by an independent specialist company- Myontec) when compared with traditional MIG Torches. The pistol grip design makes it extremely easy to detach with one click of a button and with no tools required. Due to its size, the pistol grip can easily be carried in the welders’ pocket and a pistol grip is included in has standard in every Ergoplus torch package.

Features:

A low torch head temperature is extremely important.to help reduce the consumption of consumables. The Trafimet Ergoplus torch heads operate much cooler than ever before, helping to reduce consumable usage. With a redesigned cooling structure, on the water-cooled torches, the consumption rate of consumables is greatly reduced. On continuous welding at 350 amps the contact tip heat on the Ergoplus 500 doesn’t exceed 170 C° – At least 30% cooler than previous water-cooled torches.

The water connections and hose solutions on the Trafimet Ergoplus torches are a remarkable result of the company’s R&D work in the field of connectors. The material used in its designs has been updated to EPDM, which is more flexible and durable than previous hose material. The inner structure of the rear box has also been redesigned to avoid any kinking in the water hoses.

One of the most significant improvements to the Ergoplus water-cooled torches are the well protected hose package and water hoses inside. They have a new protective hose which has much lower surface friction. The importance of the low friction of the protective hose cannot be underestimated. When the welder is moving with the welding torch, the hose package is often lying on the floor. With the lower friction surface, the torch does not stick to the floor, but moves smoothly without snagging. Similarly, the low friction surface prevents the hose package from getting caught on corners or edges.

With the Ergoplus water cooled torches, they are fitted with double ball joint, this makes the movement of the torch virtually limitless and keeps the whole of the torch in perfect balance.

The hose package and the coaxial cable on the Ergoplus torches have also been significantly updated, for improved service life.

There are only four consumable parts on the Trafimet Ergoplus, the gas nozzle, contact tip, gas diffusor, and contact tip holder.

The Trafimet Ergoplus 26 – 36 – 400 – 500 – 555 are supplied with Trafimet “Quick Release” nozzles for quick and east nozzle removal.

Trafimet Ergoplus torches have been fitted with a sealed microswitch trigger. It is more reliable than the alternative mechanical solution which has an open contact exposed to dirt, dust, and humidity. The microswitch on the Trafimet Ergoplus is IP67 rated, with a much higher standard than other electrical components on competitor’s welder torches, ensuring longer life and reliability.

The Trafimet Ergoplus torches are fitted are fitted with the euro connector as standard.

Genuine Trafimet Ergoplus consumable parts are compatible with old torch versions and most other European brands using Binzel type consumables