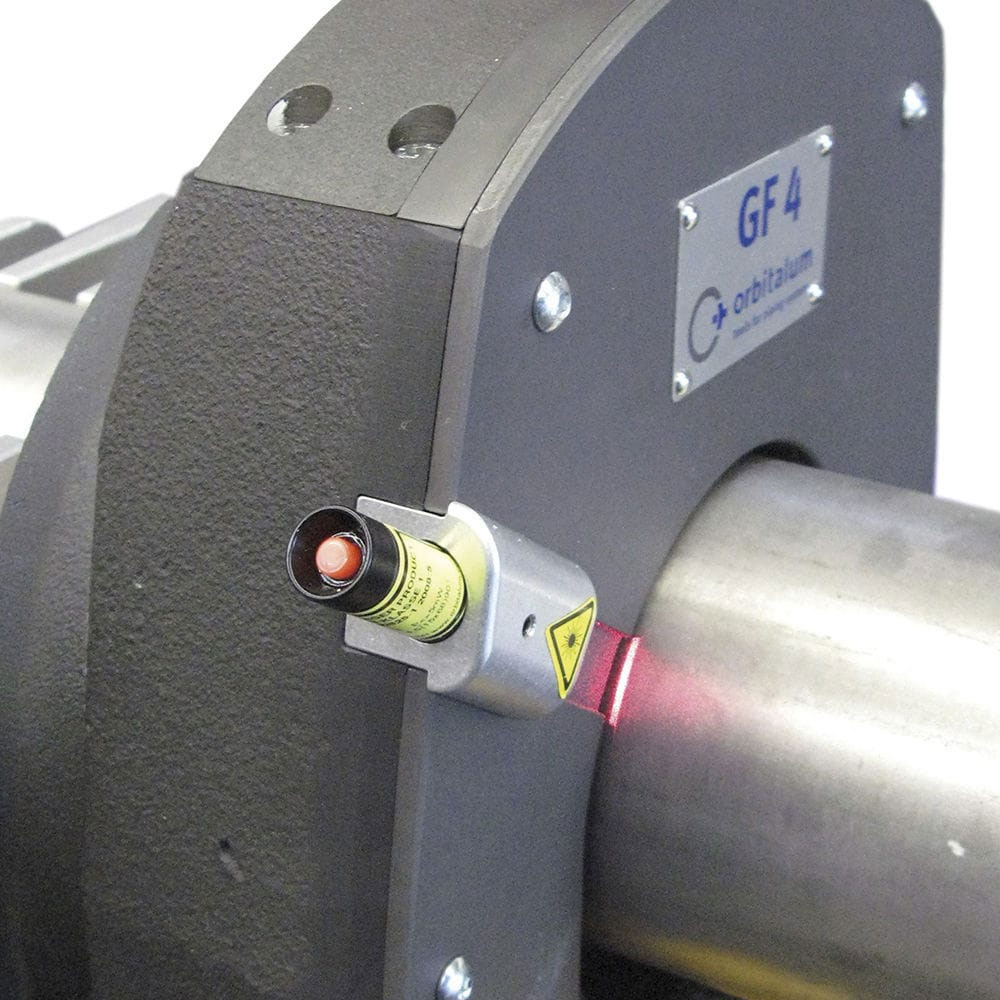

Orbitalum GF4 Tube Cutting & Bevelling Machine

Product Overview

-

Combined with their ergonomic design the GF 4 saws offer significant advantages during the industrial prefabrication of pipeline systems. The basic requirements for producing high-quality welds on pipes (be it manually or with automated welding technology) is a precise perfectly square and burr free cut or bevelled pipe end. The GF 4 saws are designed to cut and bevel pipes in high-alloy steel (stainless steel), low- and unalloyed steel, plastics, cast materials and non-ferrous metals easily and in just seconds. The GF 4 saws use the "Planetary Cutting" method accompanied by high performance HSS blades. The powerful clamping system is designed to hold the workpiece securely but without any deformation of the workpiece.

Read more

Features:

Stainless steel clamping attachments for protection against contact corrosion when working with high alloy steels.

Two position clamping jaws to reduce chatter and enable smaller length of pipe to be machined.

Reversible clamping jaws for preparing thin- or thick-walled pipes.

Optimized speed range 215 rpm), ideal for cutting high-performance materials such as Hastelloy®, P91, etc.

An ergonomically-designed motor handle for a safe and comfortable operating position, which also enables easy cutting of elbows

Integrated line laser to determine the exact cut-off point.

Multifunctional tool for all adjustments on the machine.

Swivel cable with a quick-disconnect coupler for easy replacement of the power cable.

Optimized saw blade guard protects the user against flying chips and comes with a measuring port.

Also available with automatic (AVM) or manual feed (MVM) modules on request.

Automatic feed module AVM, This intelligent solution continuously controls the cutting speed depending on the torque and the parameter settings. The AVM improves the handling of the GF 4 machines and stops automatically after the cutting process.

Manual feed module MVM, This manually operated feed module facilitates the cutting and bevelling of pipes, with the use of a hand wheel. The machine head rotates easily and with minimal effort around the pipe with a constant feed.

Specification:

Cutting Capacities;

Tube OD 12 to 120mm

0.472” to 4.724”

Minimum Tube ID with Ø 63 mm saw blade: 21mm

Minimum Tube ID with Ø 2.480" saw blade: 0.827”

Minimum Tube ID with Ø 68 mm saw blade: 16mm

Minimum Tube ID with Ø 2.677"saw blade: 0.630”

Minimum Tube ID with Ø 80 mm saw blade: 4mm

Minimum Tube ID with Ø 3.150"saw blade: 0.157”

Wall thickness (Material Dependant) 1 – 9mm

0.039” – 0.354”

Power: 1.8KW

2.41Hp

Electronic variable cutting speeds with restart inhibitor: 40 – 215rpm

Approximate Noise level at the workplace: 79 dB (A)

Vibration level (according to DIN EN 28662, part 1) < 2.5m/s2

Dimensions (L x W x H) 480 x 325 x 680mm

18.9” x 12.8” x 26.8”

Approximate weight of machine: 55.0Kg

121.2lbs

Included as Standard: Transportation case, Set of stainless steel clamping attachments, Saw blade 790 042 064, Mounting plate, Tool set, Saw blade lubricant GF TOP 790 060 228, Special gear oil 790 041 030, Operating instructions and spare parts list.

Depending on the delivery location there may be additional carriage charges applicable. When this is the case, you will be contacted by a Customer Service advisor to confirm.