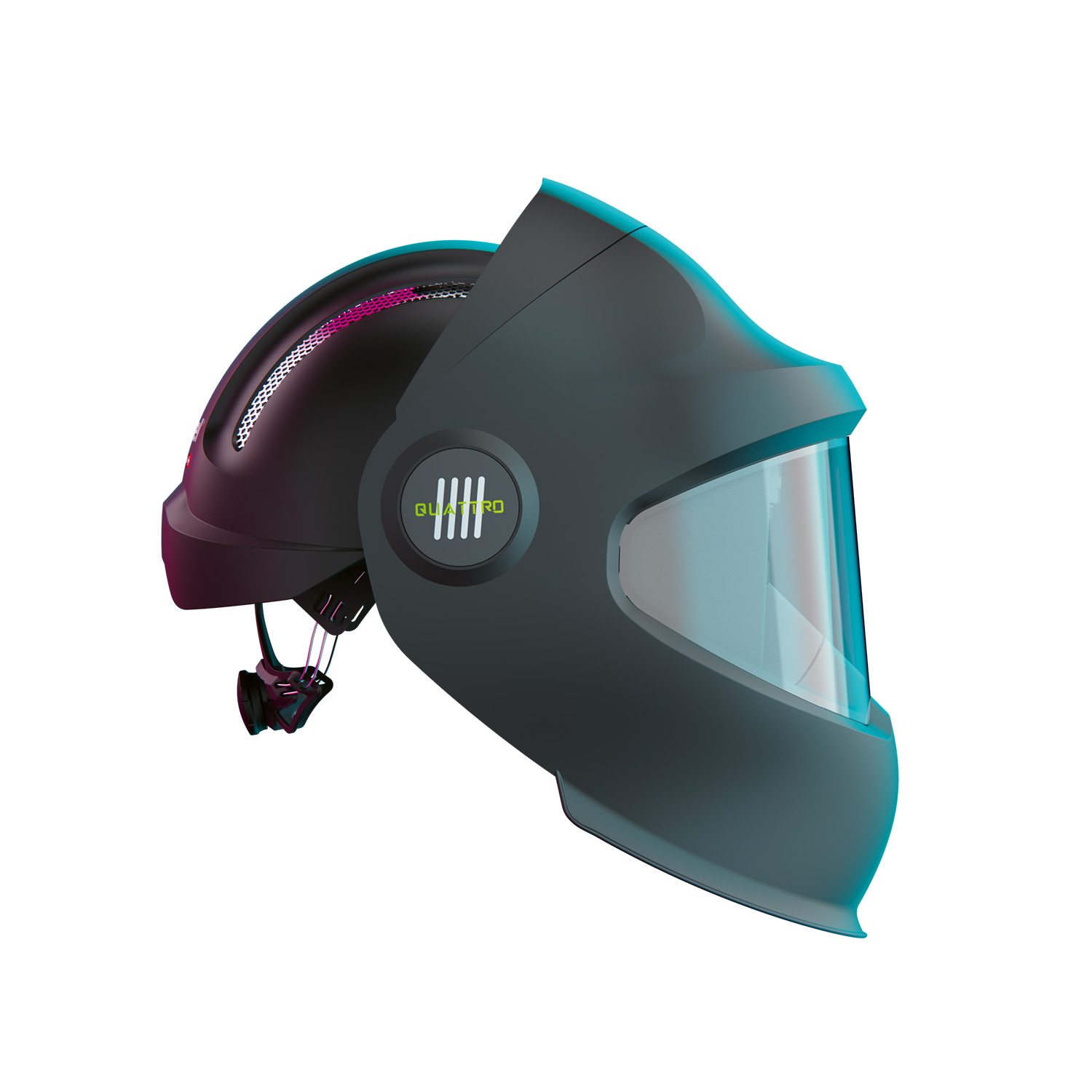

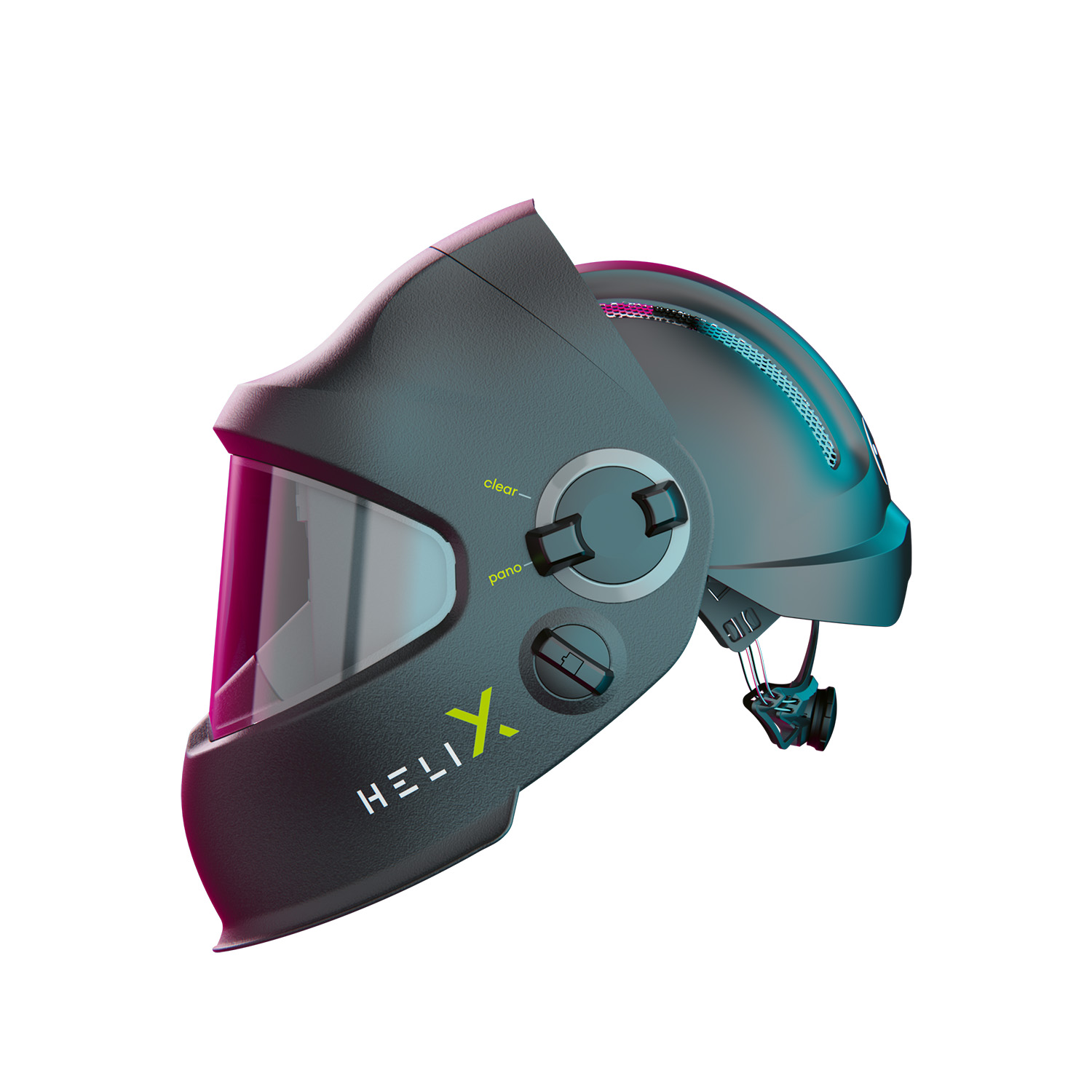

Optrel Helix Quattro ADF Welding Helmet & Hard Hat 3/4-13

Product Overview

-

The Optrel Helix Quattro ADF welding helmet and hard hat features an internally mounted slide up ADF, which achieves a perfect 1/1/1/1 rating under the EN379 standard for Auto Darkening Filters – Optical class, Scattered light, Homogeneity and Angular dependence. The unique Optrel Helix slide up concept, allows the welder to choose the protection required for each application with a single turn. Complete welding tasks with the ADF down and proceed to grinding and sanding by sliding the ADF up inside the helmet, revealing a totally clear visor with 180° viewing area.

Read more

Unlike other flip up welding helmets that place the auto darkening filter on the outside, the Optrel Helix uses an internal sliding system which allows the ADF to remain inside the clear grinding visor. Not only does this protect the ADF from weld spatter and scratches, it also dramatically reduces the ongoing replacement lens costs, as only one outer protection lens is required as opposed to two on other flip up designs. When the ADF is fully retracted, it is positioned on top of the head so the welding helmet remains perfectly balanced, this is in contrast to other flip designs which cause the helmet to be front heavy which can lead to neck and head strain.

Helix Quattro gets its name from achieving a perfect rating of 1/1/1/1 within the EN379 standard making it ideal for use in heavy industrial applications. The level 1 angular dependence rating allows the operator to see the welding area without distortion and in perfect clarity, regardless of the welders position and viewing angle. The patented nose cut out in the auto darkening filter brings the viewing area much closer to the welders’ eyes. This increases peripheral vision by 6 x and prevents the protective screen from misting as warm air from the mouth does not come into contact with the ADF.

Optrel Shadetronic® technology automatically adjusts to the correct shade protection level by measuring the light intensity of the welding arc using a total of 5 arc sensors – one central and four corner mounted. The Helix Quattro delivers perfect protection between shade levels 4 – 13 automatically, negating manual adjustment and eliminating the chance of incorrectly setting protection levels. Shade level 14 is achievable with the addition of a shade +1 inner lens.

Optrel Helix Quattro is suitable for a range of applications of up to 500 amps.

Using Optrel Fadetronic technology, the opening of the anti-glare display can be continuously adjusted after welding, fading out unpleasant afterglow. Fadetronic is a feature which is particularly useful in high ampere applications, as eye fatigue is significantly reduced due to the display opening smoothly and adapting to the eye.

The unique and environmentally friendly Optrel re-charge energy concept ensures that the welding helmet remains charged and ready for use. Thanks to the latest solar technology, a rechargeable lithium-polymer battery is recharged by welding light or ambient light. In addition, the battery can also be charged directly with any USB charger via a micro-USB interface. Battery replacement is avoided and the environment is protected.

The Helix range comes fitted with Optrel IsoFit® headgear, the ultimate in wearer comfort. The IsoFit cradle is the only head band available that enables the wearer to adjust width, length and height simultaneously, with the turn of a single rotary wheel. An ingenious cable hoist system expands and contracts to give a glove like fit, applying equal pressure at every contact point. This ensures there is no pinching, slipping or chafing, offering unrivalled comfort and practicality.

IsoFit is the perfect companion if you have to weld for long periods of time or need to work in multiple positions and want the helmet to remain in place. Despite the headband or cradle being the interface between the helmet and the wearer, it is often overlooked by manufacturers and users alike. The Optrel IsoFit headgear system combines technology and comfort, resulting in improved productivity and safety in welding applications. Optrel IsoFit ® can be dismantled in just a few seconds and cleaned with soap and lukewarm water to maintain hygiene.

The hard hat fitted inside the Helix range is an industrial safety helmet meeting EN 397 standards. The hard hat can quickly and easily be removed should it no longer be required.

For respiratory protection use in conjunction with Optrel Swiss air which has been designed to work flawlessly with Helix welding helmets.

The compact size and shape of Helix helmets allows the welder to work in constrained environments such as when working inside vessels.

Weight: 620 grams.

EN379 classification:

Optical class: 1

Scattered light: 1

Homogeneity: 1

Angular dependence: 1

Shade levels

ADF retracted / clear view: shade level 1 – perfect for sanding and grinding

Non-reactive shade level: 3

Manually activated shade levels: 8-13

Automatically activated shade levels: 4-13.

Hard hat conforms to EN 397 standards.

ADF outer lens & grinding visor meets EN166 Optical class 1, B = medium energy impact, 120 metres per second (268 mph).

Included as standard: Welding helmet, Optrel IsoFit® Headgear, bag, micro USB cable, front cover lens.

Exclusive 3 Years Warranty on all Optrel Welding Helmets excluding Batteries when registered.