Optrel Helix CLT Welding Helmet & Swiss Air PAPR Package

Product Overview

-

The Optrel Helix CLT & Swiss Air PAPR package combines the Optrel Helix CLT welding helmet and Swiss Air TH3P rated PAPR system, which is ideal for fabricators who specialise in TIG welding applications where visibility of the weld pool is critical.

Read more

A unique flip up welding helmet and ultra-lightweight TH3 PAPR system mounted on a back pack harness provides unrivalled comfort, safety and versatility in a single package.

Meets TH3 standards which only allow a maximum particulate ingress of 0.2%.

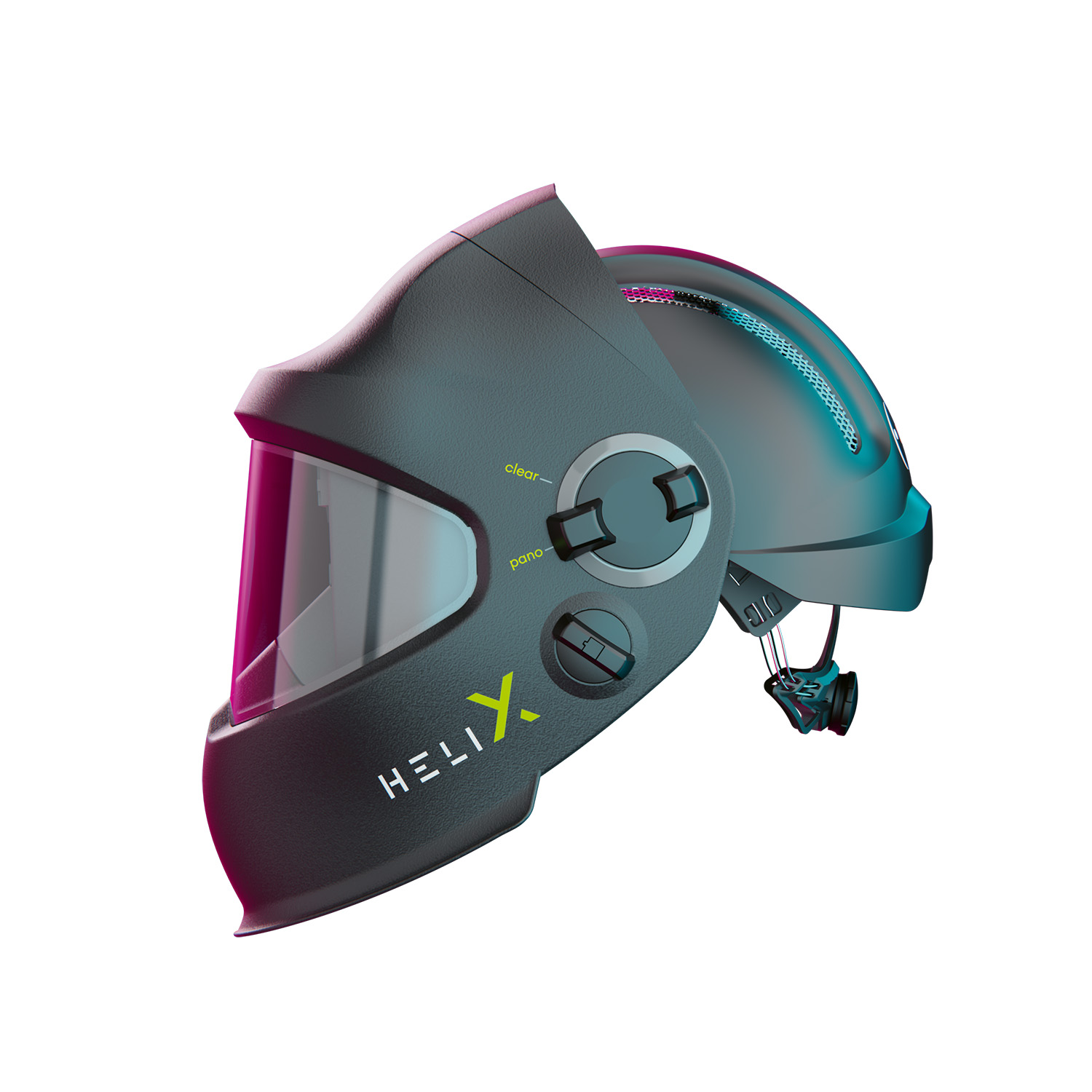

Helix CLT

The Optrel Helix CLT ADF welding helmet and hard hat features an internally mounted slide up ADF which uses Crystal Lens Technology for unrivalled clarity and true colour recognition of the weld pool when in dark state. The unique Optrel Helix slide up concept, allows the welder to choose the protection required for each application with a single turn. Complete welding tasks with the auto darkening filter down, and proceed to grinding and sanding by sliding the ADF up inside the helmet, revealing a totally clear visor with 180° viewing area.

Unlike other flip up welding helmets that place the auto darkening filter on the outside, the Optrel Helix uses an internal sliding system which allows the ADF to remain inside the clear grinding visor. Not only does this protect the ADF from weld spatter and scratches, it also dramatically reduces the ongoing replacement lens costs, as only one outer protection lens is required as opposed to two on other flip up designs. When the ADF is fully retracted, it is positioned on top of the head so the welding helmet remains perfectly balanced, this is in contrast to other flip designs which cause the helmet to be front heavy which can lead to neck and head strain.

Shadetronic ® The patented Optrel Shadetronic technology features on the entire Helix range of welding helmets. It is of critical importance that the correct shade is selected in order to provide the adequate protection when welding. Unfortunately, this process is often neglected meaning that shade levels are never adjusted, compromising performance and safety. Shadetronic sensors permanently measure the intensity of the welding arc, regulating the level of protection automatically across the entire range of shade levels from 4-12 . Optimal protection is achieved without ever needing to adjust the welding helmet. Shadetronic technology is ideal for hot start at the beginning or during the crater fill, slope out at the end of the welding process, or simply when welding with different current strengths.

Fadetronic is patented Optrel technology which manages the ADF’s changes from dark to light after the welding process has been completed. This eliminates the unpleasant afterglow associated with slope out or high-ampere applications. Eye fatigue is significantly reduced thanks to the fluid opening of the display, allowing the eyes to adapt back to light more gradually.

The Helix range has a total of 5 arc sensors – one central and four corner mounted, ensuring the auto darkening glare shield is activated and deactivated perfectly, even in the most difficult lighting conditions and positions during welding.

The unique and environmentally friendly Optrel re-charge energy concept ensures that the welding helmet remains charged and ready for use. Thanks to the latest solar technology, a rechargeable lithium-polymer battery is recharged by welding light or ambient light. In addition, the battery can also be charged directly with any USB charger via a micro-USB interface. Battery replacement is avoided and the environment is protected.

Sensitivity Function prevents the ADF lens from being prematurely activated in certain lighting environments or if a number of welders are working in close proximity. The Super High sensitivity setting can used if the welding current is extremely low preventing the ADF from activating.

The shells of the Helix range of welding helmets are compact and feature a smoke and particle repellent shape, making them suitable for overhead welding applications.

True colours can be seen by the welder thanks to the specially developed UV / IR filter on the Helix CLT.

The Helix range comes fitted with Optrel IsoFit® headgear, the ultimate in wearer comfort. The IsoFit cradle is the only head band available that enables the wearer to adjust width, length and height simultaneously, with the turn of a single rotary wheel. An ingenious cable hoist system expands and contracts to give a glove like fit, applying equal pressure at every contact point. This ensures there is no pinching, slipping or chafing, offering unrivalled comfort and practicality.

IsoFit is the perfect companion if you have to weld for long periods of time or need to work in multiple positions and want the helmet to remain in place. Despite the headband or cradle being the interface between the helmet and the wearer, it is often overlooked by manufacturers and users alike. The Optrel IsoFit headgear system combines technology and comfort, resulting in improved productivity and safety in welding applications. Optrel IsoFit ® can be dismantled in just a few seconds and cleaned with soap and lukewarm water to maintain hygiene.

The hard hat fitted inside Helix welding shields is an industrial safety helmet meeting EN 397 standards. The hard hat can quickly and easily be removed should it no longer be required.

Weight: 640 grams.

EN379 classification:

Optical class: 1

Scattered light: 1

Homogeneity: 1

Angular dependence: 2

Shade levels

ADF retracted / clear view: shade level 1 – perfect for sanding and grinding

Non-reactive shade level: 2

Manually activated shade levels: 7-12

Automatically activated shade levels: 4-12.

Hard hat conforms to EN 397 standards.

ADF outer lens & grinding visor meets EN166 Optical class 1, B = medium energy impact, 120 metres per second (268 mph).

Swiss Air

The Optrel Swiss Air half-mask gives you maximum protection and comfort by combining a powerful motor and high efficiency filtration unit with a fully adjustable, lightweight half mask. The Swiss Air respiratory protection system works independently from PAPR Welding helmets, PAPR grinding visors and PAPR hoods. This allows the operator to combine the highest levels of particulate protection with standard personal protective equipment (PPE) such as; face shields, goggles, helmets, welding helmets, spectacles and ear defenders. This makes this the Swiss Air the most versatile PAPR system available.

The core element of the Optrel Swiss Air system is a ventilated half mask that completely covers the wearers mouth and nose area, supplying them with purified air. The clean air is supplied to the half mask via a Y-hose from the Swiss Air’s miniaturised blower system, which is comfortably positioned on a carrying harness positioned on the wearers back – similar to an ultra-lightweight rucksack. The user is then constantly in a "positive pressure air system", which prevents contaminated air from entering the mask. The positive pressure inside the mask also helps to make breathing easier, thus reducing breathing fatigue associated with traditional elastomeric masks and disposable respirators – especially during manual labour.

The half-mask itself is made of hard wearing flame retardant fabric. It has been designed in such a way that it can easily be adapted to fit all face shapes and sizes utilising a fully adjustable headband and pull cord. The Optrel Swiss air concept eliminates the need for costly and time consuming face fit tests and safely works with operators that have beards and facial hair.

IP 54 splashproof and dust-tight rating makes Swiss Air suitable for use outside and in dusty environments.

Features:

Optrel Swiss Air TH3P system provides 99.8% protection against fine dust, fume and mist, equivalent to 10 x greater protection when compared to a traditional FFP3 disposable respirator or half mask. Even harmful viruses such as Covid 19 are filtered from the air.

The blower unit has an automatic air flow calibration function and is supplied with a long life 14h battery for extended all day working.

When used with the optional Swiss Air Controller – positioned on the chest section of the shoulder strap, all functions are controllable when wearing the unit; overview of filter contamination, battery charge status, air flow control, on/off switch and altitude and temperature compensation.

Blower Unit with automatic air flow control:

Flow rate: Level 1: minimum 100 l/min

Level 2: minimum 115 l/min

Level 3: minimum 130 l/min

Noise level: 70db (A) maximum.

Alarms: Optical (with the Swiss Air Controller) and audible alarm for low and very low battery, clogged or no filter, plus low flow.

Dimensions (L x W x H): 250mm x 170mm x 50mm

Weight: 1200 grams (incl. filter, belt and battery)

Half Mask:

Material: Ripstop textile

Inlay: Polyurethane foam.

Valves: 2 exhalation valves with silicone membrane

Head & Neck Band Material: Neoprene and elastic.

Hose:

Material: POM and silicone.

Length: 180 mm (elastic, up to 355 mm excl. Y-hose)

Internal diameter: 21 mm

Battery Pack:

Type: Rechargeable Li-Ion. 3,6 V / 6,5 Ah / 23.4Wh

Operating time: Level 1: 14 hours

Level 2: 12 hours

Level 3: 8 hours

(with new filter at room temperature)

Charging time: Approximately 6 hours

Included as standard: Swiss Air Blower unit C/W controller, Comfort half-mask, Hose system, Head and Neck strap, Harness, Battery, Battery Charger, TH3P R SL filter. Optrel Helix CLT Welding helmet, Bag.

Warranty: Swiss Air – 2 years from date of sales for manufacturing and material defects, 6 months warranty for battery.

3 Years Warranty on all Optrel Welding Helmets excluding Batteries when registered.