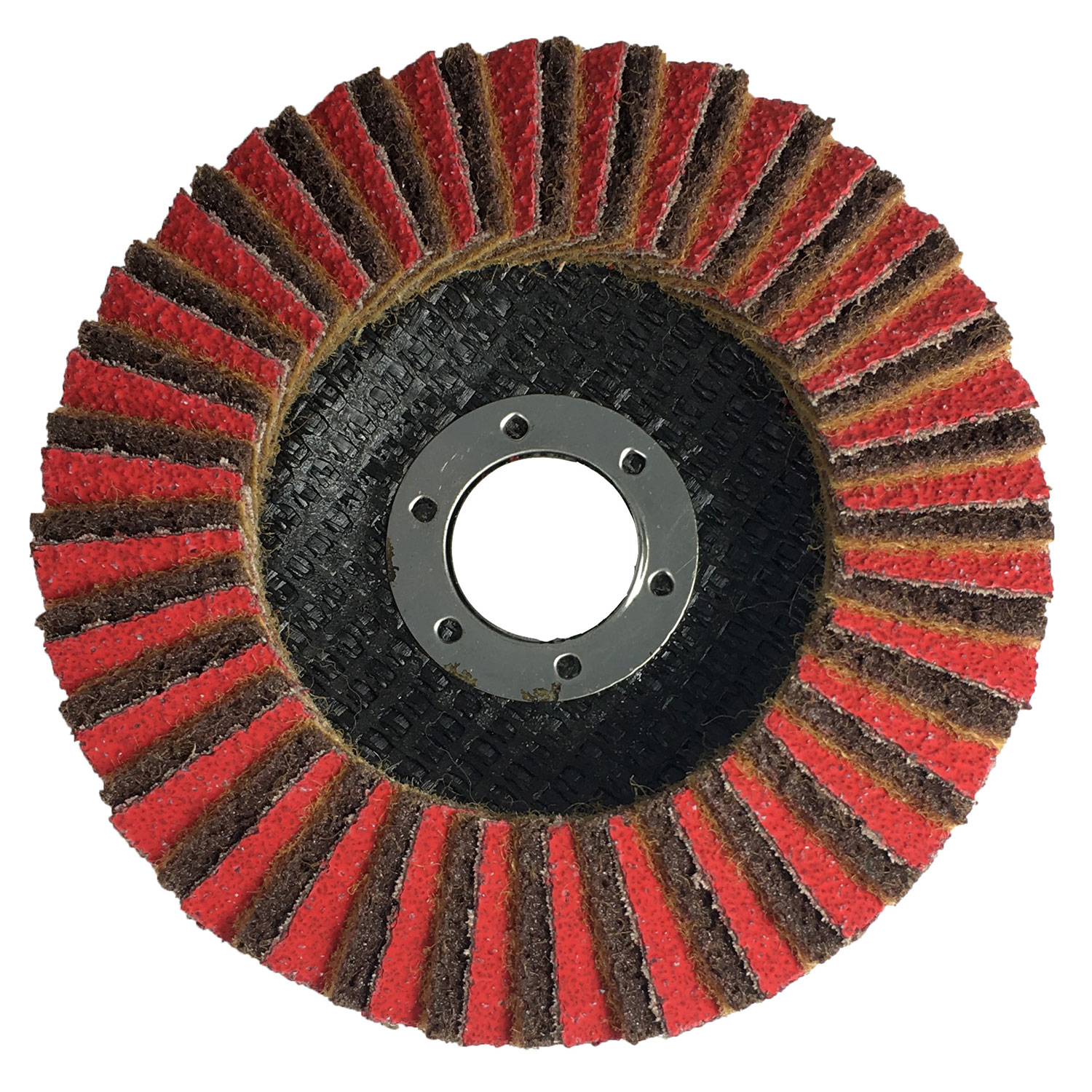

Cibo RCD Combination Flap Discs

Product Overview

-

The RCD (Rapid Combi Disc) combines a perfect match between two technically advanced abrasive materials with varying abrasive capabilities. A polycotton extra flexible abrasive backing cloth with grinding aid and a surface conditioning material with a very rapid and even grinding capacity. Both materials are designed to give even wear on both the abrasive cloth and surface conditioning material The revolutionary RCD combination flap discs allows you to remove stainless steel TIG weld seams and leave a flawless extremely high-quality fine brushed or satin finish in just one single operation. The RCD is also extremely useful for finishing angles, improving rough surfaces and refining any coarse grinding lines. An RCD can be used in a wide range of applications on stainless steel, aluminium, soft metals and special alloys.

Read more

The RCD flap discs work the most effectively when used on variable speed Inox grinders and best results are achieved when run at around 6,000rpm. However, they can also be used on full speed angle grinders and will give low heat generation, plus give much more controlled material removal when compared with standard flap discs.

Heavy grinding and finishing at the same time are also possible with RCD ultra-Coarse disc. This is thanks to the ceramic coated cloth and the surface conditioning material between the ceramic flaps which limits the grinding depth. The dampening function of the surface conditioning flaps also guarantees a greater amount of control during the grinding process. The ultra-coarse grade RCD is a great solution when grinding on aluminium, this is down to the cool running and resistance to loading.

RCD Medium combination flap discs are the most popular, you can use the RCD medium on any tubular stainless-steel section and remove TIG welds and leave a perfect 240 grit satin finish in one simple operation.

RCD Very Fine combination flap discs can easily remove finer TIG welds on stainless steel hand rails or box section to leave a 320 grit satin finish in one simple action.

Enormous time and significant cost savings on most applications with only one operation instead of the traditional three.

Controlled material removal ensures an improved finish, even for inexperienced users.

Even finish with consistent and low Ra-value

Lower heat generation for longer disc life and better finish

Eco-friendly due to less waste being created by only having to discard one disc.