From twist drills to rotabroach cutters

For over 100 years the most common method of producing holes in steel work was with conventional-type twist drills. The 1970’s saw the first ever annular hole cutter which became known worldwide as the Rotabroach cutter. With the introduction of TCT cutters 15 years later, mag drills have evolved from the two man operation “widow makers” weighing 45kg to now just weighing 8.5kg.

The Widow Maker

Stephen A. Morse of East Bridgewater, Massachusetts invented the twist drill in 1861. They have remained the most  common way of producing holes, up to this present day. The early drill bits were manufactured by producing two grooves opposite sides to each other in a round bar, the bar was then twisted to produce the flutes. Nowadays, the flutes of the drill bit are ground into the bar by rotating and passing the bar over a grind wheel which precision grinds the flutes. The force and energy required to the produce the large holes with the twist drills meant that steelworkers had to use heavy portable magnetic drilling machines. The magnetic drilling machines were very large and could weigh up to 45kg. This meant it was a two-man operation because not a single man could lift the machine. They were nicknamed “The Widow Maker” because the drill bit would often snag, spinning the machine and knocking the operators from the structure.

common way of producing holes, up to this present day. The early drill bits were manufactured by producing two grooves opposite sides to each other in a round bar, the bar was then twisted to produce the flutes. Nowadays, the flutes of the drill bit are ground into the bar by rotating and passing the bar over a grind wheel which precision grinds the flutes. The force and energy required to the produce the large holes with the twist drills meant that steelworkers had to use heavy portable magnetic drilling machines. The magnetic drilling machines were very large and could weigh up to 45kg. This meant it was a two-man operation because not a single man could lift the machine. They were nicknamed “The Widow Maker” because the drill bit would often snag, spinning the machine and knocking the operators from the structure.

Rotabroach Annular Hole Cutter System

In the early 1970’s, Dough Houghen invented the Rotabroach Annular Hole Cutter System. As with many innovations, the market was not ready to accept the concept of cutting holes with an annular cutter. Houghen shared the annular cutter idea with a few drill bit manufacturers, but they were all very content with producing drill bits. Finally, he decided to take the idea directly to the fabricators and steelworks who saw the benefits straight away and became extremely interested in the concept.

Benefits of the Rotabroach Annular Hole Cutter System

The Rotabroach cutters invented by Dough allowed the operators to produce holes in just one pass which made them up to three – four times faster than conventional drill bits. Even though the fabricators and steelworkers liked the Rotabroach cutters, it did not solve the problem of having to move around heavy magnetic drill machines. The geometer and multiple cutting teeth of the Rotabroach cutters are designed to cut just a 5mm section around the holes periphery, unlike conventional drill bits which cut away all the material of the hole. Not only did this offer the benefit of faster cutting speeds, it also meant that they required far less motive force and energy to product the equivalent size holes. This benefit allowed Doug to later reinvent the magnetic drilling machine, giving them smaller motors and magnets making them considerably lighter and weighing around 12.5kg.

Due to the Rotabroach cutter system being very light, it meant that in a workshop environment the drill could be taken to work. This made the process a lot safer and only a one-man operation.

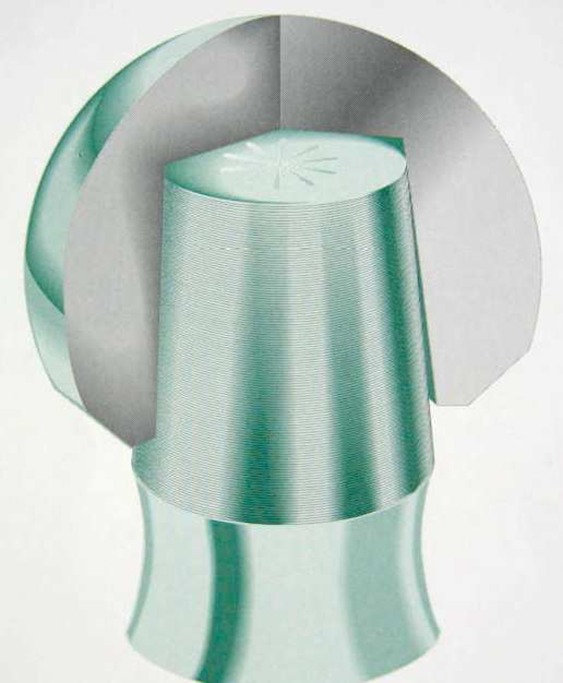

Annular Hole Cutters – High Speed Steel

The next phase in the evolution of the Rotabroach annular hole cutter came 13 years later in 1983. Using a similar concept to the Rotabroach system, Michael Beharry invented an annular hole cutter made from high-speed steel. A higher percentage of cobalt used in these high-seed steel cutters, allowed for faster cutting speeds and made the cutters slightly more durable on the higher grades of structural steels. Even though the M42-type cutters would cut faster and produce slightly more holes. The extra cobalt typically exhibited lower toughness which could make the cutters slightly more brittle and prone to breaking in certain conditions, when compared to the original type of cutters.

TCT Broaching Cutters

Two years later in 1985, Mikiya Toshio and Shoji Michihiro invented the first TCT annular hole cutters. The TCT cutters allowed for even faster cutting speeds and could drill through a much wider range of materials. TCT broaching cutters have become ever more popular and are now available in a range of diameters up to 150mm. Today the CarbideMax range of TCT broaching cutters are made with a unique six point cutting geometry and use the highest quality tungsten carbide tipped teeth. They have a thinner body wall meaning even less material is being removed during the broaching process. When it comes to producing holes the CarbideMax delivers up to 15% faster drilling speeds, plus the benefit of four to five times longer life when compared to the traditional HSS broaching cutters. The premium-grade Tungsten Carbide teeth will also work well in materials that are typically harder such as stainless steel, cast iron, and most grades of structural steel.

Fein KBE36 Mag Drilling Machine

As with the Rotabroach cutters, the CarbideMax thinner wall and tooth geometry allows for increased cutting speeds. This means that less motive force and energy is required to produce an equivalent-size hole. Nowadays, smaller machines with faster drilling speeds are available to run the CarbideMax TCT cutters. The new Fein KBE Mag Drill is a small and lightweight single-speed endurance magnetic core drill that offers unique performance and service life even under the most challenging conditions in the workshop and on the construction site. Combined with the Fein HM Ultraspeed cutters or alone, the KBE36 will outperform and outlast any other mag drill on the market

No magnetic core drill in the world: drills faster or drills more! The Fein KBE36’s outstanding cutting performance has never been seen before thanks to speed and torque curve with cutting speeds of up to 70 m/min, ideal for HM ULTRA and HM ULTRA SPEED core drill bits.

Twice the productivity combined with the perfect result. Thanks to rapid work progress, you can drill up to 60 holes rather than the 30 that used to be possible at the same time.

View the video to see how the Mag Drill outperforms all competition.

Click to view the Fein KBE36 Mag Drill here.